Shipping cargo tracking and monitoring for marine asset visibility

-

Refrigerated containers

Refrigerated containers Refrigerated containersKeep an eye on refrigerated containers as they travel through the supply chain and monitor key parameters for sensitive loads.

Refrigerated containersKeep an eye on refrigerated containers as they travel through the supply chain and monitor key parameters for sensitive loads. -

Dry containers

Dry containers Dry containersTrack location and monitor status of dry containers to improve operational efficiency, cargo security and customer service.

Dry containersTrack location and monitor status of dry containers to improve operational efficiency, cargo security and customer service. -

Chassis

Chassis ChassisEnsure smooth intermodal management with asset tracking. Get containers out of the port and to their destination quicker.

ChassisEnsure smooth intermodal management with asset tracking. Get containers out of the port and to their destination quicker. -

Gensets

Gensets GensetsUse remote visibility to understand genset health so repairs can be made before they’re in rotation.

GensetsUse remote visibility to understand genset health so repairs can be made before they’re in rotation. -

Vessel and crew

Vessel and crew Vessel and crewStay connected after leaving the port with a local cellular network that ensures ship-to-shore communication.

Vessel and crewStay connected after leaving the port with a local cellular network that ensures ship-to-shore communication.

Visibility

Compliance

Optimization

Cargo security and integrity

ORBCOMM CrewView

Resources

Frequently asked questions

Container tracking technology provides shipping lines with the location and status of containers across the global supply chain, allowing them to optimize operations, differentiate offerings, diversify income streams and provide customers with value-added services. It also benefits third parties including shippers, beneficial cargo owners (BCOs) and importers by informing operational decisions and mitigating logistics challenges.

Additionally, by enabling unprecedented visibility of containers and cargo, container tracking technology can help shipping lines optimize routes and asset utilization and contribute to the sector’s efforts to meet decarbonization targets.

Container tracking technology uses GPS, IoT devices, sensors and communication networks to provide visibility into container location, condition and security throughout the supply chain. This information can be used to optimize planning and forecasting. IoT-enabled devices monitor container location while also tracking conditions like temperature, humidity, movement and door status. In dual-mode systems, the network switches between cellular and satellite, optimizing coverage and providing cost-effective connectivity to ensure uninterrupted monitoring during transit. This can enhance supply chain visibility and improve operational efficiency.

Yes, container tracking technology can significantly boost container security. Telematics systems using IoT technology allow companies to monitor the location and status of containers throughout transit. These systems can detect unauthorized access, device tampering or deviations from planned routes. Alerts can be triggered when a container door is opened unexpectedly or when it enters specified areas, enabling swift responses to potential theft or breaches. This proactive monitoring helps detect potential theft, reduce losses and enhance overall supply chain security.

Container monitoring technology improves asset utilization by providing data on the location and status of shipping containers. This information allows businesses to track container movements, optimize routing and reduce idle time, helping ensure containers are used more efficiently. Telematics also helps identify underutilized assets, enabling better allocation and planning. Additionally, monitoring helps detect the likelihood of cargo damage or loss, reduce downtime caused by repairs or replacements and improve overall operational efficiency and asset turnover.

By maximizing the use of each container, companies can lower operational costs, improve turnaround times and increase overall productivity in their supply chain. IoT data can also offer deeper insights into the flow of containers to inform port optimization strategies.

Reefer container monitoring technology tracks key parameters like location, temperature, humidity and power status. This allows shipping lines to see if conditions stay within safe limits and quickly catch any issues like temperature changes or power loss. The data is sent via satellite or cellular networks to a central platform, so operators can keep tabs on each container’s status and make adjustments remotely, helping to prevent cargo spoilage and improve overall control.

Alerts are triggered if there are deviations in temperature, door openings or power issues, allowing crews or operators to take immediate corrective actions. This helps ensure the quality and safety of perishable goods and provides full visibility over a container’s condition throughout the journey.

ORBCOMM’s vessel container monitoring technology keeps you connected to containers at sea by leveraging satellite and cellular technology to provide continuous visibility into their location and condition. GPS-enabled devices transmit the container’s position, ensuring you always know where your cargo is, even in deep at sea, where connectivity has traditionally been difficult, ensuring uninterrupted data flow.

In addition to location tracking, ORBCOMM’s container tracking solution monitors critical conditions such as temperature, humidity and door status, protecting sensitive goods like perishables or pharmaceuticals. Alerts notify you of route deviations, unauthorized access or environmental changes, enabling quick action to address potential issues.

This advanced connectivity enhances operational efficiency, minimizes risks and helps deliver seamless supply chain management from departure to arrival.

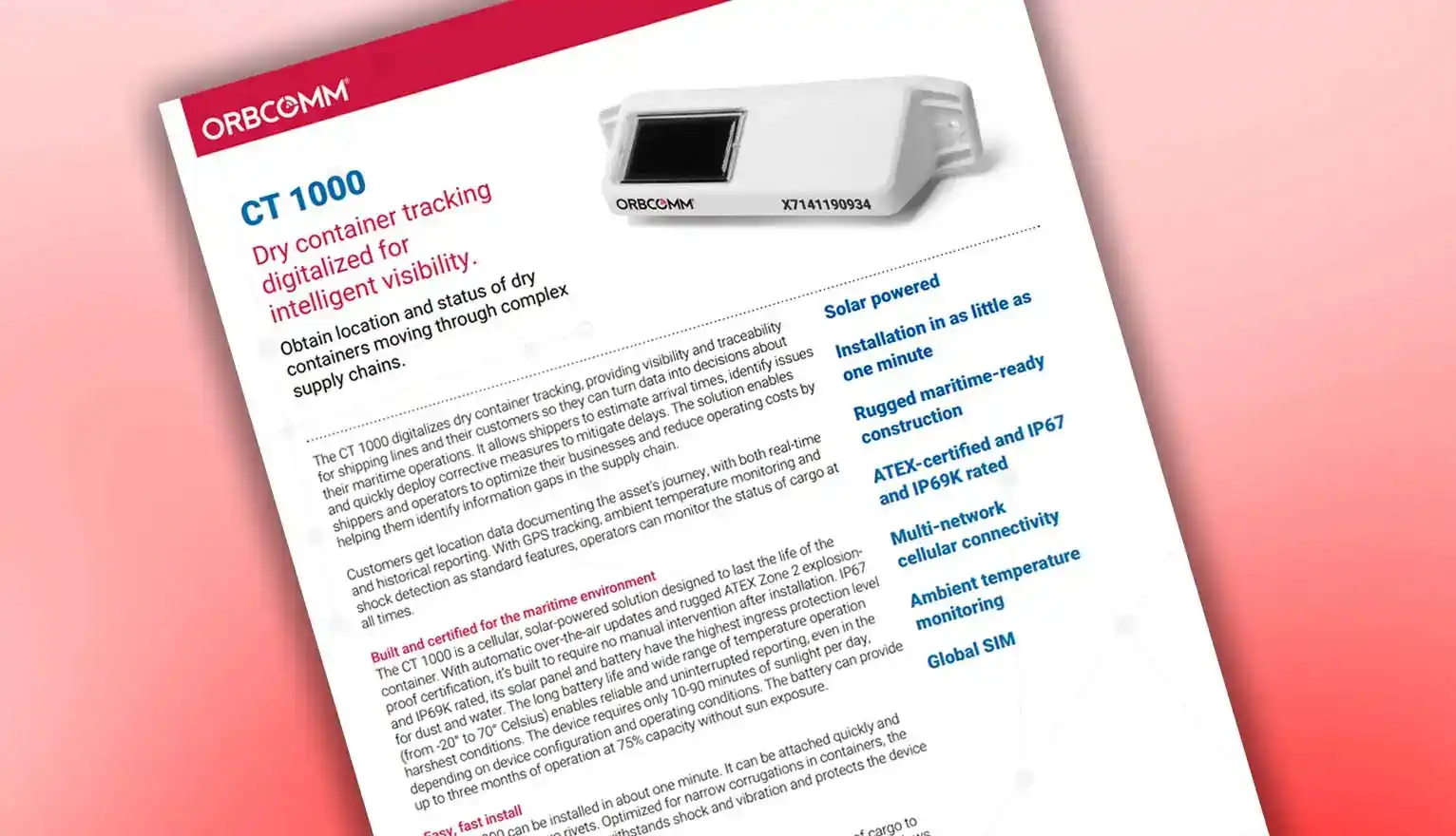

Dry container tracking technology enhances operational efficiency by enabling improved container utilization, reduced idle time and optimized route planning. Combining versatile IoT devices, sensors, applications and multiple global connectivity options, the latest dry container IoT solutions allow stakeholders to maintain situational awareness; protect non-perishable but temperature-sensitive cargo; streamline handovers and delivery; improve customer service; reduce operational costs and more.

It can also increase security by detecting unauthorized access and help reduce chances of cargo damage. This level of supervision minimizes delays, prevents losses and supports better decision-making, ultimately saving costs and improving asset management. Additionally, it helps shipping companies optimize shipments and provide customers with more accurate ETAs.

Shipping container management technology improves sustainability by optimizing resource use and reducing the environmental impact of logistics operations. Thanks to advanced asset management telematics solutions, companies can track container movements, minimize empty container trips and improve route planning to reduce fuel consumption and emissions.

Monitoring systems also help maintain cargo conditions, reducing spoilage and waste in perishable goods. Moreover, improved scheduling and container turnover reduce congestion at ports and warehouses, further minimizing the carbon footprint of transportation and storage operations.